High-Resolution Aerial Imagery for Government

EagleView Cloud

See with Clarity. Decide with Confidence.

Make Confident Decisions With Aerial Imagery

EagleView Cloud is our new aerial imagery and software service.

Featuring clear imagery, precise measurements and easy-to-use analysis tools, EagleView Cloud helps county and local governments work efficiently and make critical decisions.

Multiple imagery options are available. Choose our clear and detailed 1-inch oblique images, value-oriented 3-inch orthogonal images or another imagery type aligned with your needs.

See Critical Details with 1-inch Aerial Imagery

with each pixel representing one square inch of ground area.

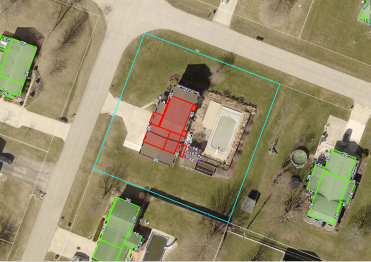

Using 1-inch oblique imagery, property analysis is easier and faster.

- Residential Property Assessment: Determine quality grade and condition, identify building materials and see detached structures.

- Commercial Property Assessment: Analyze building features, roof design and the presence of machinery and equipment.

- Public Works: Analyze roads and infrastructure.

EagleView Cloud is the only way to secure our 1-inch oblique imagery, our clearest and most detailed imagery.

EagleView Cloud: What Is Included

High-Resolution Imagery

View properties with clear, natural-looking imagery. Oblique (side angle) and orthogonal (top down) images are included.

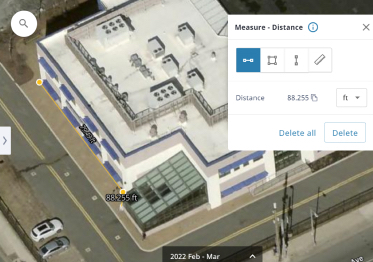

Viewing and Measurement Software

Measure distance, height and area on images with our user-friendly tools.

Image Archives

View historical orthomosaic and disaster response imagery.

Imagery Enhancement Options

Choose a Better GSD

Options range from 6-inch to 1-inch ground sample distance (GSD).

Receive Images More Often

Choose image delivery aligned with your needs: twice per year, once per year, or once every two or three years.

See More Historical Images

Access three additional years of historical oblique imagery, based on calendar years.

Join Our Disaster Response Program

After qualifying events, images are provided to assist with disaster response and recovery.

Benefits for Government Departments

Additional Analytics Tools

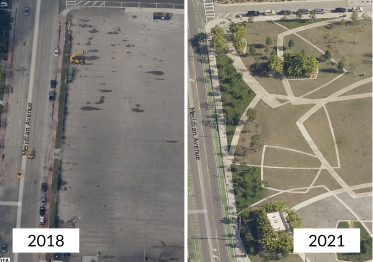

ChangeFinder

Automatically detect property changes from year-to-year, making property assessments easier and faster.

Sketch Inspect

Find inaccurate and missing property sketches using CAMA system records and aerial imagery.

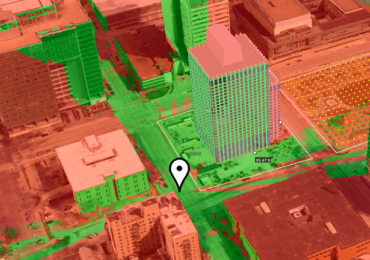

3D Mesh

Visualize a new building and analyze its impact on a neighborhood in a three-dimensional environment.

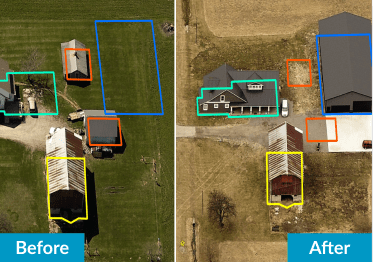

Aerial Imagery for Disaster Response and Recovery

When every second counts, images from the air provide valuable context to assist with decisions being made on the ground.

Aerial imagery is a critical tool for governments after severe weather events. Using aerial imagery, damage can be evaluated safely and first responders can plan search and rescue missions. Property assessors use imagery to reassess damaged properties and calculate lost tax revenue. Then, when it is time to recover and rebuild, aerial imagery makes the planning process easier.